Walter designed Emma’s rig based on traditional schooner rigging and adding some more modern (and convenient) elements. Many of the traditional wooden components were manufactured at home in a nearby workspace.

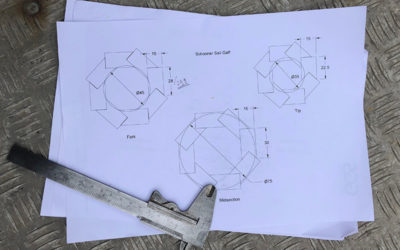

Belaying pins

A series of holes were made in the gunwale for belaying pins, so we had another opportunity to learn a new skill. We have a few woodworking machines... but no lathe, so W. turned these at the local community center woodshop. They are sturdy, handy, beautiful and...

Constructing the gaff

Well, there is the traditional approach followed by Henry. You take a tree of suitable size or a beam (spruce or larch are fine) and plane it to shape according to Skene’s scantling rules. The gaff fork is made from choice pieces of oak with the grain following the...

Getting ready to sail

Before you can finish the boom, you need to know where your out-haul and reefing points go. For that you need to have the sail. We were very happy to work with Holmsegel from Schleswig who are not only knowledgeable in modern sail making but also can show some...

Stepping the Masts (June 2019)

The first time we stepped the masts was a big event. Many locals from the village of Sillerslev were present; we even made it into the local news!

Various Woodworking Projects

Blocks. Parrel beads. Pegs. All of the beautiful thingie-bobs.

Building Hollow Spars (and Clubs)

Text here ....

Splicing a schooner rig

There are many good things to be said about galvanized standing rigging, but early on we decided not to use galvanized wire but stainless steel because we didn't want to service endless lengths of stays with gunky stuff that sticks to your hands and cloths every time...

Manufacturing Mast Hoops

Text allgm.

Heavy parts: The Bowsprit

Another huge piece – the wood was stored and aged and shaped in Henry's workshop. She'll eventually get some netting so that we can access the kluver sail and have a nice hammock above the waves.

Heavy parts: The Mast

The masts are simply two larch trees planed and sanded round.